Many think brewing beer is complicated, but the reality is that it’s a very natural process. Most of the beer we all drink is made from the same four ingredients. Barley, water, hops and yeast, yes that’s all it takes to create the world’s most refreshing drink. The basic idea is to extract the sugars from grains (usually barley) so that the yeast can turn it into alcohol and CO2, creating beer.

There are three main ways to brew– extract brewing, partial mash, and all-grain. They all involve heating water with grain, adding hops and boiling the mixture, cooling it, adding yeast and barrelling or bottling to allow for carbonation. What makes these processes different is how they approach the first stages of the brew.

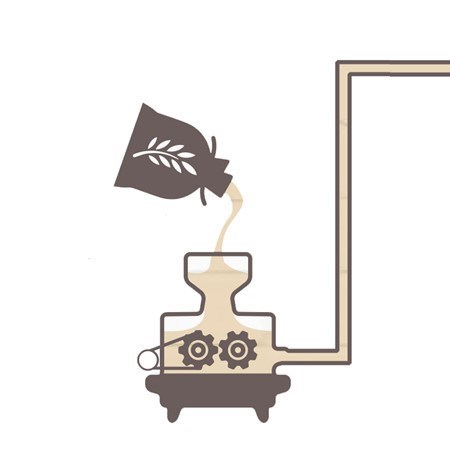

Mashing and Lautering

The first stage is called “mashing”, which is the process of activating the natural enzymes in the yeast to turn their starch into sugar, which the yeast will need later. This provides the initial characteristics of the brew in terms of colour, flavour and body. The mashing involves very hot water to activate the enzymes and create the base liquid of the beer, known as “wort”.

Next comes lautering, which is when the wort that has been produced is separated from the grain by pouring more heated water over it to rinse off any remaining sugars. Lautering makes sure that the yeast can do its work.

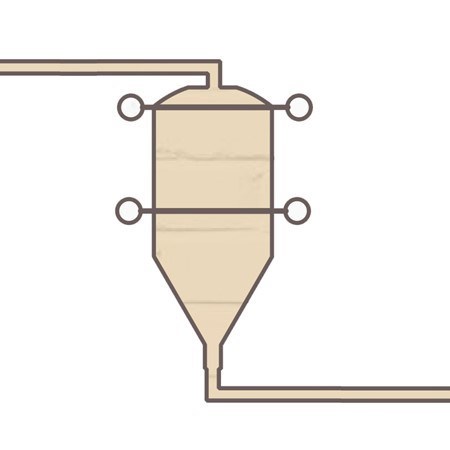

Boiling and Fermentation

Boiling comes next, which sees a very high temperature boil get rid of remaining enzymes and oxygen and stabilise the wort ready for the hops. Adding the hops is where the beer really gets its character. There's a wide variety, and brewers are constantly trying new combinations. Hops add bitterness to balance out the sugar from the wort, and they act as a natural preservative, too.

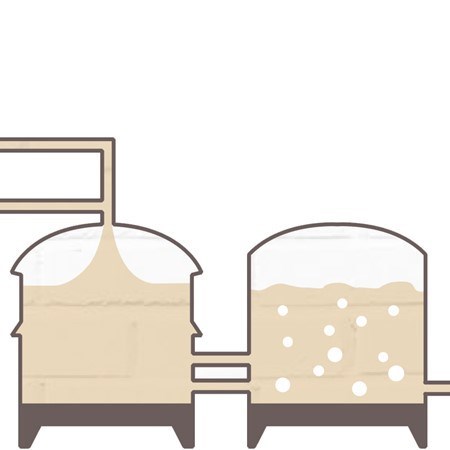

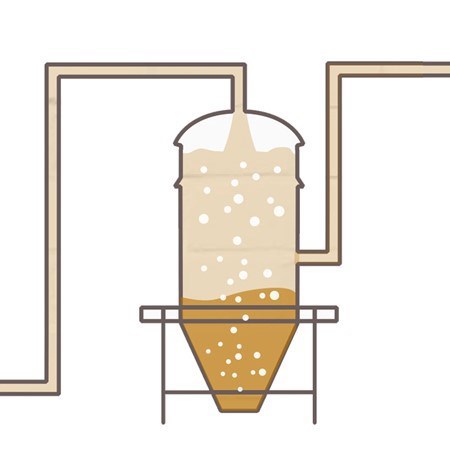

With the brewing complete, fermentation happens by quickly cooling the brew, taking an initial reading of the gravity of the brew to help work out the alcoholic content, and then adding, or “pitching” the yeast. Fermentation is a two-part process. Primary fermentation sees the yeast convert the sugars into alcohol and carbon dioxide, and secondary fermentation allows your beer’s flavours to fully open up to add complexity and a better taste.

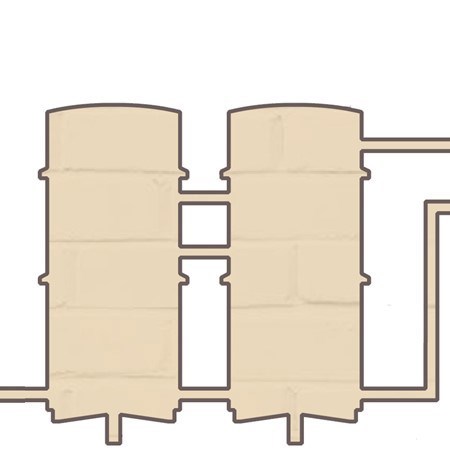

How beer is made: The eight steps

1. Mashing

2. Lautering

3. Boiling

4. Separation

5. Fermenting

6. Maturing

7. Filtering

8. Packaging

Bottling and Conditioning

With fermentation complete, the final gravity reading is taken and compared with the first to work out the final alcoholic content. Then the beer is bottled, canned or kegged and soon to be enjoyed, after a final conditioning period of at least two weeks. It is during this conditioning stage that some beers are left to naturally carbonate. Whilst making great beer isn’t a quick process, good things are worth waiting for!

Of course, there are many ways to tweak this process and many brewers do, giving us the wide range of styles we enjoy today. Many of these differences are historic. Belgium, for example, is known for strong Trappist beers, originally brewed in monasteries and with high alcoholic content. While Germany, just across the border, is the home of lager and well known for its wheat beers. This makes it very difficult to write an article that explains every possible process in full.

We’re thankful for all of the many differences in making beer nonetheless. The ability to experiment with beer laid the foundations for the craft boom and the renewed interest in the category. While the range of styles, from IPA to Porter and beyond ensures there is a beer for every occasion. If you really get to know your beer, immerse yourself in the amazing flavours and textures it can offer, you’ll be amazed what can be produced from this simple process!